Inline leak testing. Here we can pull a vacuum to get a practical check on a valve and seat.

United States Ball Corp. manufactures a wide variety of valve balls utilizing many different materials, including stainless steel, titanium, and steel. Valve balls have high pressure or critical applications, sometimes referred to as "zero leak". Many of the valve balls we produce have end-use applications utilized by the Navy, Air Force, Aerospace, and Medical. Our precision industrial valve balls include applications where the valve MUST SEAL for function.

United States Ball Corp. can manufacture valve balls in every configuration, modified balls, and design to your specification, such as Valve balls with trunnions, valve balls with slots, valve balls with splines.

Please feel free to call for assistance with your particular application.

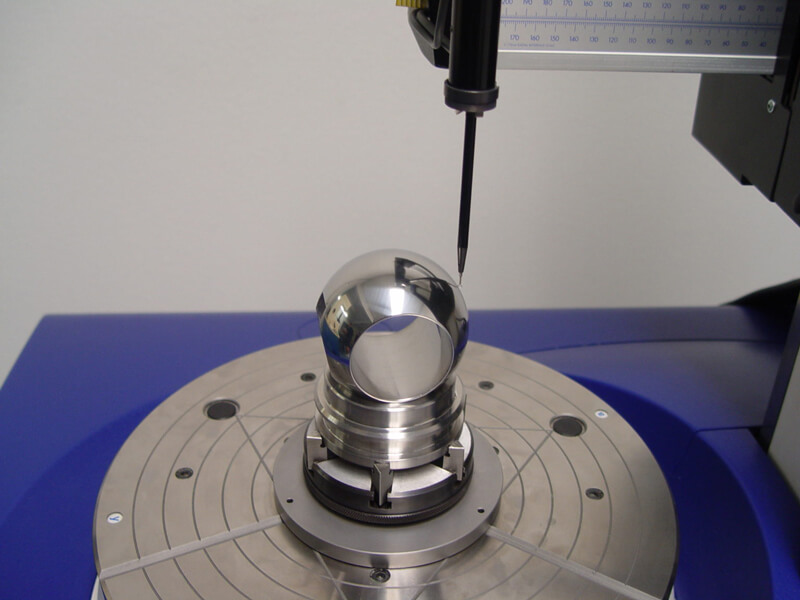

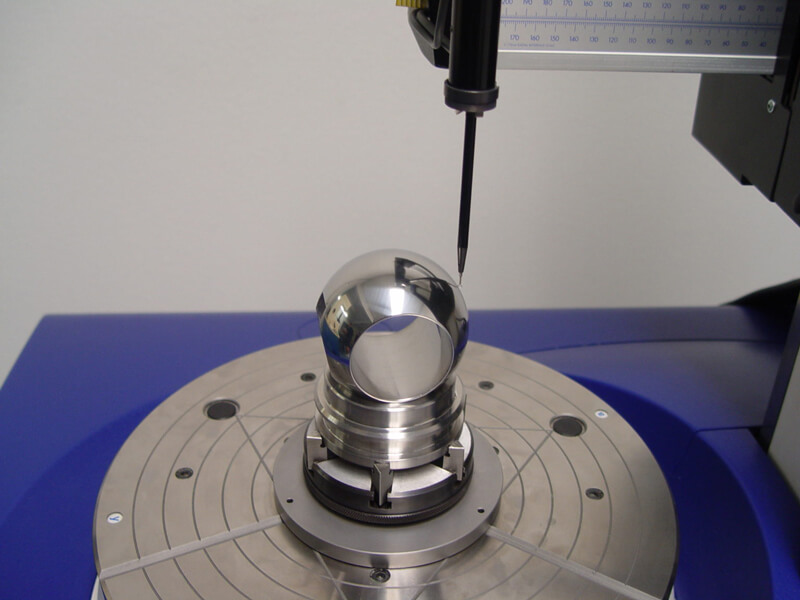

Two essential characteristics of the high-pressure valve balls are the roundness and the surface finish. Roundness, often referred to as sphericity, must be controlled, especially in the critical sealing area. The second characteristic is the surface finish. We can manufacture valve balls with extremely high roundness and high surface finish tolerances.

We manufacture valve balls from a wide variety of materials depending on the application.

Please feel free to contact us for assistance with your particular application.